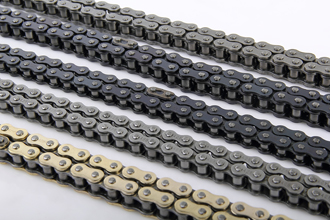

Motorcycle Chains

Under the working condition of high speed drive and intensive shock, motorcycle chains are required with strong tensile strength, strong fatigue resistance and high precision, so we have high request of the material choosing, mold precision, equipment, heat treatment, assemble technology and inspection. To achieve the target of producing high quality motorcycle chains with longer use life, high grade alloy steel materials are be used , 45Mn for plate, 20Mn for bush and 30CrMnTi for the pin; Moreover, professional heat treatment equipment and technology are adopted for further optimize the physical properties of all materials to reach the base requirement of a superior motorcycle chains.

Based on and exceeding JCAS1 design, the motorcycle chain produced by Hengjiu - which has high quality - becomes the first choice of domestic motorcycle manufacturing plants but it also is sold all over the world because of its outstanding abrasion resistance, everlasting fatigue resistance, high reliability, and its outstanding performance.

* The surface of the chain plate is precisely punched and smoothed, and the inner wall has over 80% of the bright zone.

* The final process for the plate holes includes spherical polishing and surface polishing to ensure the maximum fatigue resistance.

* The chain plate and rollers undergo shot blasting treatment to relieve stress and surface deformation, thereby enhancing the fatigue resistance.

* The chain uses evenly distributed four-sided rivets and is made of seamless small tubes, featuring extremely high strength and a longer service life.

We optimize the physical structure of all materials through professional heat treatment equipment and techniques. Additionally, we use motorcycle-specific "kilogram oil" to reduce noise and ensure a usage duration of over 25,000 kilometers.